Well made my first mini trip which was a couple hour run to have a crab fest with buds. I was running late so it's a few hours later before getting a chance to look at the numbers.

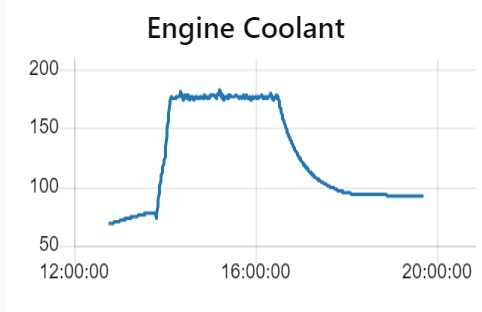

Here's the engine coolant temperature monitoring of the flow in the heater hoses.

The temperature was fairly rock solid at 175 degrees. I think the rapid fall off is simply the cooling of about 20 ft of heater hose. It would have been interesting to kick in a circulation pump for the engine coolant and see what the decline curve actually looks like.

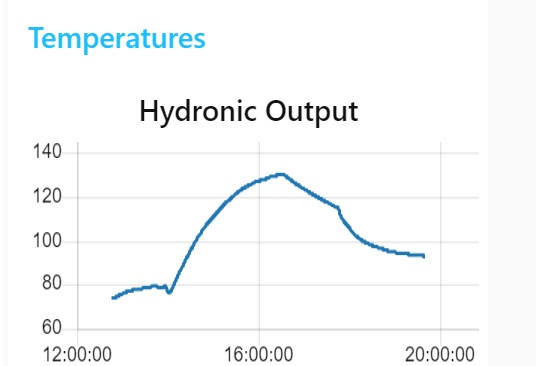

The next graph is for the two glycol storage tanks with a re-circulation pump running.

Note the maximum temperature reached was about 125 degrees after a two hour run.

This is with the engine coolant running through one ten gallon tank and constant stirring between the two ten gallon tanks.

In the above graph the increase in the decline is where I turned off the stir pump.

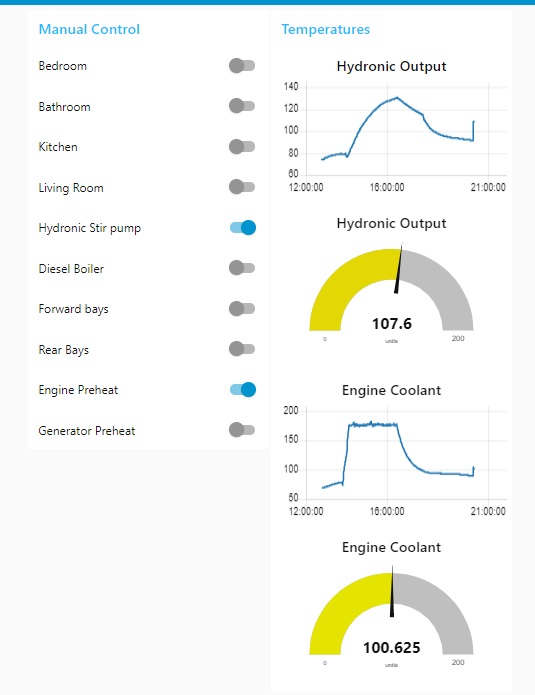

Just for grins, I decided to turn the engine pre-heat and the strip pumps on to see what would happen.

So it looks like my automation needs a sensor input of is the engine running and as long as the engine coolant is warmer the storage glycol harvest more heat by circulating the engine coolant.

I probably also should consider insulating the pipes...

Reply With Quote

Reply With Quote